Laini Kamili ya Upya Matairi ya Magari

| Ukubwa wa tairi unaoweza kuchakatwa | Chini ya 1200mm |

| Uwezo wa kila siku | Tani 3-35 kwa siku (saa 24) |

| Matumizi ya Nishati | ≤ 40 kWh/ton |

| Ukubwa wa unga wa mpira | 10-80 mesh |

| Usafi wa unga | Juu ya 99.2% |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Kila mwaka, mabilioni ya matairi ya zamani yanaunda changamoto kubwa ya "uchafu mweusi", ikilinda sayari yetu. Hata hivyo, ndani ya changamoto hii kuna fursa ya "dhahabu mweusi" yenye faida. Katika Shuliy, sisi ni watengenezaji wataalamu wa mashine za kuchakata matairi ambao wanajitahidi kubadilisha tatizo hili la mazingira kuwa biashara yako yenye faida.

Laini yetu ya juu ya kuchakata tairi kiotomatiki kikamilifu hubadilisha tairi zilizochakaa kwa ufanisi na kwa uhakika kuwa bidhaa zenye thamani kubwa: poda ya mpira laini, granules za mpira, na waya wa chuma safi sana, kuhakikisha matumizi kamili ya rasilimali. Zaidi ya yote, teknolojia yetu ya kipekee ya kuokoa nishati inaweza kupunguza matumizi yako ya umeme wakati wa operesheni kwa hadi 33%, na hivyo kuongeza faida na ushindani wako.

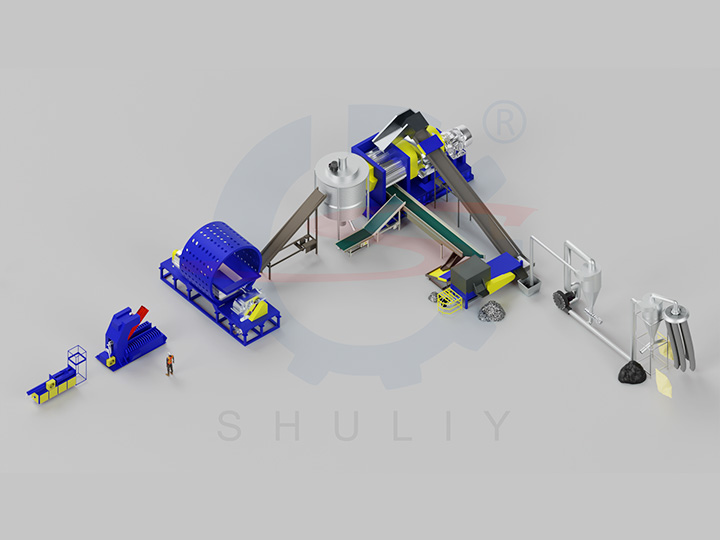

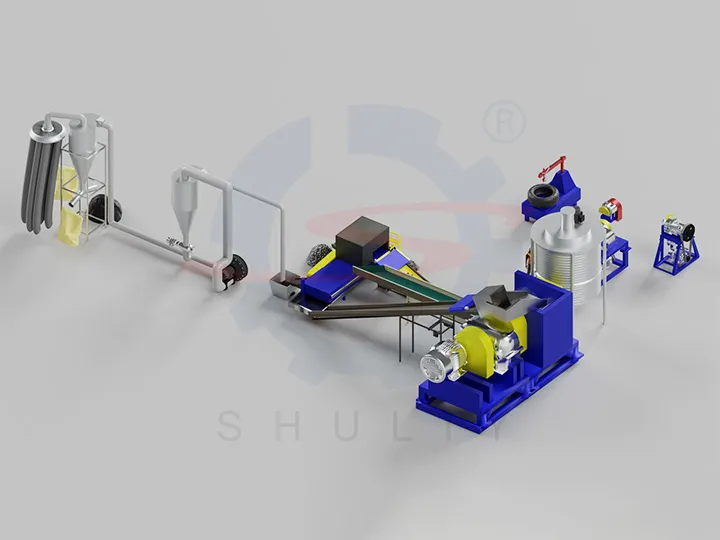

Jinsi Shuliy Mstari wa Uzalishaji wa Granule za Kivuli Unavyofanya Kazi

Tumefanya mchakato mgumu wa kuchakata tairi kuwa mtiririko kazi laini, wa kiotomatiki sana. Kwa wafanyikazi kidogo, tairi zilizochakaa hubadilishwa kwa ufanisi kuwa bidhaa zinazouzwa sokoni.

Hatua ya 1: Utayarishaji wa Kabla wa Tairi Zilizochakaa – Uondoaji Ufanisi wa Chuma cha Ndani

Tairi zilizochakaa huwekwa kwenye kitengo cha utayarishaji wa kabla. Kulingana na mahitaji yako, De-beader (Mashine ya Kuchora Waya) huondoa waya nene wa ndani, au Kikata Pete za Tairi hutenganisha kuta za pembeni, ikifuatiwa na Kitenganishi cha Waya wa Chuma. Hatua hii hutoa pete safi za chuma zenye thamani kubwa.

Hatua ya 2: Kusaga Kimsingi – Kusaga kuwa Poda ya Mpira

Tairi zilizotayarishwa kabla hupelekwa kwenye Kikata Tairi. Mfumo wake wa nguvu wa vile vya shafiti mbili hurarua kwa urahisi tairi nzima kuwa vizuizi vya mpira vya ukubwa sawa wa 50-100mm, na kuziandaa kwa hatua ya kusaga faini.

Hatua ya 3: Kusaga Faini – Kusaga kuwa Poda ya Mpira

Mab block ya mpira huingia kwenye sehemu kuu ya laini: Rubber Mill (pia huitwa mashine ya kusaga matairi chakavu). Kupitia shinikizo kubwa na hatua ya kukata ya rollers za alloy, mab block ya mpira huchanwa haraka kuwa unga laini wa mpira wa 5-40 mesh. Ukubwa wa mwisho wa mesh unaweza kurekebishwa ili kukidhi mahitaji ya soko lako.

Hatua ya 4: Utenganishaji na Usafishaji – Kupata Bidhaa za Mwisho Safi

Katika mchakato mzima wa kusaga mpira wa tairi, Vituo vya Sumaku vilivyounganishwa na Viondoa Hewa vya Nyuzi (Nylon) hufanya kazi kusafisha nyenzo. Mifumo ya sumaku huondoa waya wa chuma laini, huku viondoa hewa vikiondoa nailoni na vifaa vingine vya nyuzi. Matokeo yake ni bidhaa tatu safi, zinazouzwa: unga wa mpira wa daraja la juu, waya wa chuma laini, na nyuzi za nailoni.

Poda/Granules za Mwisho za Mpira na Bidhaa za Pili

Teknolojia na Vipengele Vyetu Muhimu

Utendaji bora huzaliwa kutoka kwa umakini usiokomaa kwa maelezo. Tutachunguza vifaa viwili muhimu zaidi katika laini ya uzalishaji wa granules za mpira.

Kinu cha Mpira: Moyo wa Laini, Chanzo cha Ufanisi

Kinu cha Mpira (mashine ya kusaga mpira) huamua ubora wa bidhaa ya mwisho na tija kwa ujumla. Ubunifu wetu unazidi vifaa vya jadi katika kila eneo muhimu:

- Rola za Msingi: Zimetengenezwa kutoka kwa aloi ya 5Cr6MnMo inayostahimili kuvaa yenye muundo wa groove mbili. Faida: Uimara wa kipekee (unaoungwa mkono na dhamana ya miaka 3) na tija ya juu kutokana na uwiano wa kasi wa 1:2.5, ambao huunda nguvu bora ya kukata.

- Mfumo wa Kuzaa: Mashine yetu ya kusaga matairi chakavu ina vifaa vya kuzaa roller ndefu mbili za safu 8. Faida: Hii inapunguza sana msuguano wa uendeshaji na joto, na kusababisha akiba ya nishati hadi 33% na maisha marefu ya mashine.

- Kipunguza Kasi (Gearbox): Kipunguza yetu cha tairi chakavu kinatumia kipunguza gia za hyperbolic na muundo wa safu mbili za gia. Faida: Hutoa torque ya juu na uwezo wa mzigo huku ikihakikisha utendaji wa kelele ya chini, wa kuaminika na wa kudumu.

Kikata Tairi: Nguvu Ghafi kwa Tairi Yoyote Iliyochakaa

Kikata tairi ni mashine nyingine muhimu kwa laini nzima ya usafishaji tairi kiotomatiki, na utendaji wake ni muhimu. Wetu umejengwa kwa nguvu na uvumilivu:

- Vile vya Kusaga: Vimetengenezwa kutoka kwa chuma cha aloi mchanganyiko kilichotibiwa joto maalum. Faida: Hii hutoa usawa kamili wa ugumu na uimara, ikiwaruhusu vile kurarua tairi zenye ukanda wa chuma kwa muda mrefu kabla ya kuhitaji matengenezo. Unene wa blade hufikia hadi 100mm kwenye miundo mikubwa zaidi.

- Aina ya Kina ya Kasi: Tunatoa safu kamili kutoka mfumo wa 900 hadi mfumo wa 1800. Faida: Kwa nguvu kuanzia 64.5 kW hadi 328.5 kW kubwa na tija kutoka tani 2 hadi zaidi ya 20 kwa saa, tuna mashine inayofaa inayolingana na kiwango chako cha operesheni na matarajio yako.

Uwekezaji Mwerevu Ulioundwa kwa Mafanikio Yako

Kuwekeza katika kuchakata tairi kunamaanisha kuwekeza katika tasnia yenye ukuaji wa juu na endelevu. Laini yetu ya kuchakata tairi kiotomatiki kikamilifu ndiyo mshirika wako wa kuaminika zaidi katika mradi huu, iliyoundwa ili kutoa faida bora ya uwekezaji, gharama za chini za uendeshaji zinazoendeshwa na teknolojia ya msingi ya kuokoa nishati, na uzalishaji wa muda mrefu, wa kuaminika unaoungwa mkono na muundo thabiti.

Ni Wakati wa Kubadilisha "Uchafu Mweusi" kuwa "Dhahabu Yako Mweusi". Wasiliana na wataalamu wa kiufundi wa Shuliy leo kwa pendekezo la bure, lililobinafsishwa na uchambuzi wa kina wa ROI!