Beyond the Machine: Delivering a Complete PE PP Recycling Line to Nigeria

Sourcing industrial machinery from China for an international project often involves more than just selecting the right equipment. For many businesses, the greatest challenge lies in coordinating logistics, especially when a complete production line is sourced from multiple suppliers. This case study explores how we assisted a Nigerian client in not only acquiring a high-performance hard plastic washing line but also in solving a critical shipping puzzle to complete their PE PP recycling line Nigeria project.

The Challenge: A Logistical Puzzle for a Multi-Supplier Project

The client, an experienced machine consultant in Nigeria, initially approached us for a single piece of equipment: a heavy-duty plastic crusher. However, through direct communication, we understood the full scope of his project. He was assembling a complete system to process hard plastics like PE, PP, and PVC, and had already sourced a pelletizing machine a few years ago.

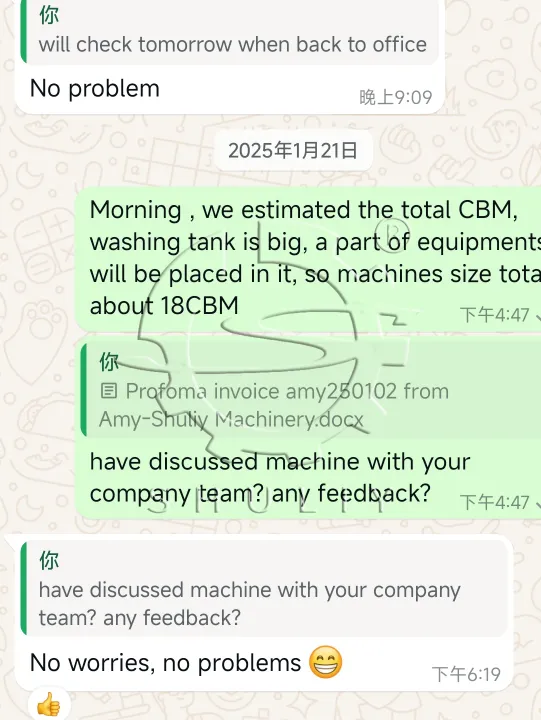

This created a significant logistical and financial challenge. The core problem was no longer just about machine specifications; it was about freight consolidation. To make the project financially viable, our entire washing line and the other supplier’s pelletizer had to fit perfectly into a single shipping container. The client’s project hinged on a precise plastic machinery shipping solution, as any miscalculation would lead to immense extra costs and delays.

Our Solution: An Integrated Approach of Equipment and Logistics

Understanding that the client’s primary concern was the successful consolidation of his shipment, we expanded our role from a mere equipment provider to a project partner.

Engineering a Robust Washing Line:

First, we configured a complete and robust hard plastic washing recycling line designed for the client’s specific materials. The system included:

- A 600-type heavy-duty crusher to efficiently break down the rigid PE and PP materials.

- A high-speed friction washer to scrub and remove contaminants.

- A V-shaped floating washing tank to separate plastics by density.

- n efficient dewatering combination of a mashine ya kufuta maji ya wima na a horizontal centrifugal dryer to ensure the material was ready for the next stage.

- An automatic knife sharpener to minimize maintenance downtime.

Providing a Definitive Shipping Solution:

This was the critical step. Instead of leaving the logistical burden on the client, we took initiative. Our team proactively contacted the client’s other supplier to obtain the exact dimensions and specifications of their pelletizing machine. With all the data in hand, we created a detailed container loading plan. We were then able to give the client the definitive confirmation he needed: “Yes, both systems will fit.” This assurance, backed by concrete data, removed the biggest obstacle to his project.

The Result: A Successful Project and a Trusted Partnership

By addressing the client’s most critical pain point, we built a foundation of trust that went far beyond the equipment itself. The client proceeded with the order, confident that the complex logistics were under control. The complete PE PP recycling line Nigeria project moved forward successfully, with all machinery co-loaded and shipped exactly as planned.

This case demonstrates our commitment to client success. We understand that in international trade, providing a reliable plastic machinery shipping solution can be just as valuable as the machinery itself. We are not just manufacturers; we are partners dedicated to ensuring your project is a success from the factory floor to your final destination.