高性能HDPEリグリッドリサイクルライン、375kg/hの生産量でテストに成功

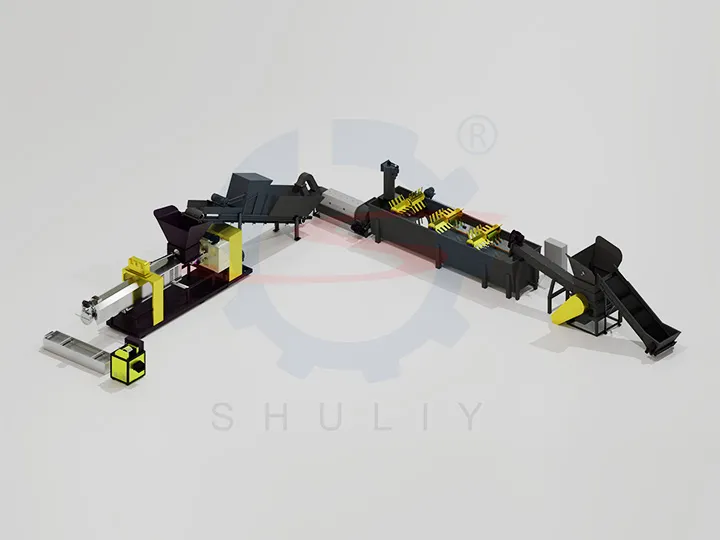

HDPE再生リサイクルライン

当社の施設は、お客様の多様なニーズを満たす効率的なプラスチックリサイクルソリューションの設計と製造に特化しています。当社の最近のプロジェクトの 1 つは、設計容量 1 時間あたり 300 キログラムの HDPE 再生リサイクル ラインに関係しています。実際の試運転期間中、パフォーマンスは予想を上回り、時速 375 キログラムという驚異的な出力が達成されました。

HDPEリグラインドリサイクルプラントの特徴

このリサイクル ラインは、原材料が粉砕された HDPE ドラムとボトルである当社のクライアントのために、粉砕された HDPE プラスチックを処理するために特別に設計されました。

試運転中、リサイクルラインはその堅牢な性能を実証し、当初の設計能力よりも25%高い毎時375キログラムの生産量を達成しました。これは、動作の安定性と品質を維持しながら、より高い負荷を処理できるマシンの能力を示しています。

なぜこのリサイクルラインを選ぶのか?

- カスタマイズ可能な容量: プラスチックリサイクルライン 100kg/h から 500kg/h 以上の範囲の生産要件を満たすように調整できます。

- エネルギー効率: 高度なエンジニアリングにより、パフォーマンスを損なうことなく消費電力を削減します。

- 幅広い用途: PET、HDPE、LDPE、PPなどの幅広いプラスチックのリサイクルに適しています。

- 操作の容易さ: 直観的な設計と自動化により、ユーザーフレンドリーで保守が容易になります。

プラスチックリサイクル事業者のメリット

このような高性能リサイクル ラインへの投資は、生産性の向上を確実にするだけでなく、プラスチック廃棄物を貴重な原材料に変えることで持続可能な実践にも貢献します。企業は、高品質のリサイクルペレットを販売することで、環境フットプリントを削減し、業界規制を遵守し、新たな収益源を開拓することができます。