Planta Semisemiautomática de Reciclaje de Neumáticos para Producción de Polvo de Caucho

| Capacidad Diaria | 1-3 toneladas por día |

| Fuerza de motor | 30–150 kW (según el modelo) |

| Eficiencia de Separación Acero-Nylon | 99.2% |

| Tamaño del Polvo de Caucho | 10-40 mallas (2.5-0.63mm) |

| Diámetro aplicable | menos de 1200 mm |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

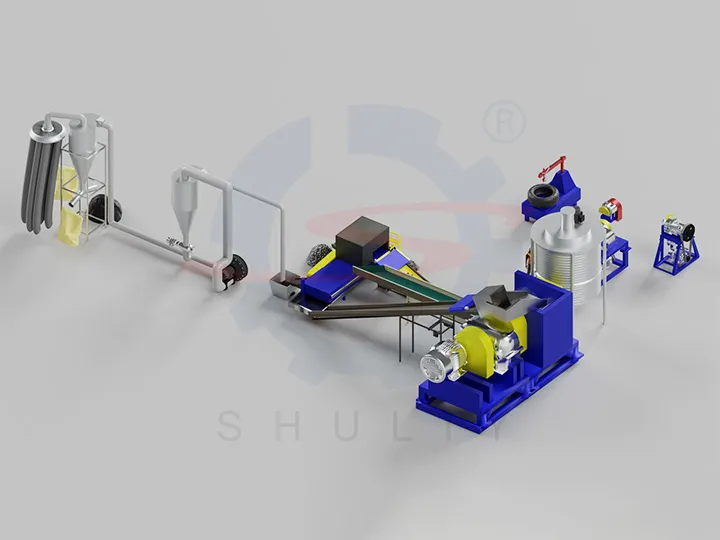

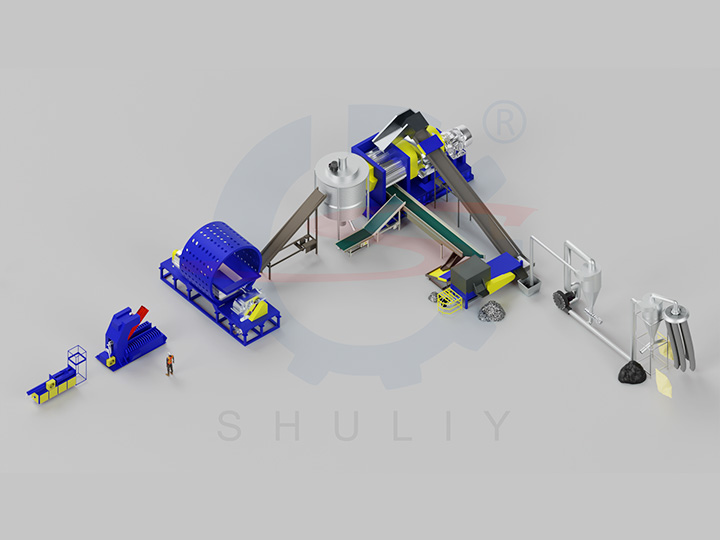

Nuestra planta semiautomática de reciclaje de neumáticos está diseñada para procesar neumáticos usados de varios tamaños en polvo de caucho de alta calidad, alambre de acero limpio y fibra de nylon opcional. Esta versátil línea de máquinas de reciclaje de neumáticos incluye una cortadora de anillos, cortadora de tiras, cortadora de bloques, desalambrador de talón, molino de polvo de caucho y un separador de fibra opcional. El proceso está diseñado para una máxima eficiencia, reducción del desgaste en componentes clave y pureza optimizada del producto final, lo que la convierte en una inversión ideal para empresas de reciclaje en todo el mundo.

polvo de caucho de diferentes tamaños

polvo de caucho de diferentes tamaños gránulos de caucho triturado

gránulos de caucho triturado

Proceso de producción de polvo de caucho

El proceso comienza con la máquina de reciclaje de neumáticos que corta las paredes laterales para eliminar los anillos de acero del talón. Luego, el cuerpo del neumático se corta en tiras y bloques, que son más fáciles de manejar y alimentar en la siguiente etapa. El desalambrador de talón extrae el alambre de acero restante, protegiendo el equipo de trituración.

En la línea de producción de polvo de caucho, los bloques de caucho se muelen hasta obtener un polvo fino (20-120 mallas), con separación magnética que garantiza la eliminación de cualquier metal restante. Para neumáticos reforzados con nylon, el separador de fibra opcional aumenta la pureza del polvo de caucho al 99%.

Máquinas de reciclaje de neumáticos para el pretratamiento de neumáticos

La cortadora de talón de neumáticos es el primer paso en el proceso de reciclaje de neumáticos, diseñada para romper la pared lateral del neumático.

Después de la eliminación del talón, la cortadora de tiras de neumáticos corta el cuerpo del neumático restante en tiras uniformes. Estas tiras tienen el tamaño adecuado para alimentar la cortadora de bloques.

El cortador de bloques de neumáticos reduce las tiras de neumáticos en bloques más pequeños y manejables, haciéndolos adecuados para la alimentación en las trituradoras de caucho.

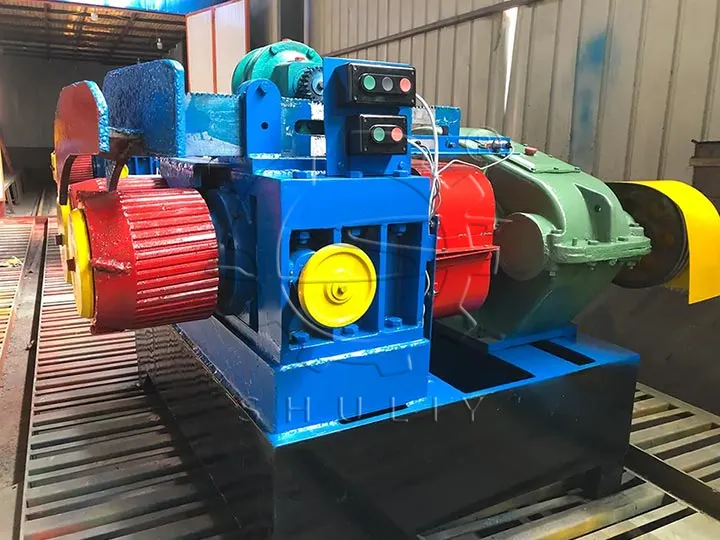

Equipo Clave de la línea: Máquina Trituradora de Caucho

La función principal de esta trituradora de caucho en la línea de reciclaje es triturar bloques de caucho preprocesados en polvo de caucho fino y de alto valor.

Específicamente, su función se puede desglosar en los siguientes puntos:

- La máquina trituradora de neumáticos procesa bloques de caucho que ya han sido pretratados (desalambrado, corte en tiras, corte en bloques) y a los que se les ha retirado el alambre de acero principal del talón.

- Utilizando dos rodillos de aleación de alta velocidad y contrarrotación con ranuras especiales, somete los bloques de caucho entrantes a una intensa compresión, cizallamiento y trituración.

- En última instancia, tritura físicamente estos bloques de caucho en polvo o gránulos de caucho, una materia prima lista para ser utilizada en la fabricación de nuevos productos como pistas de atletismo, baldosas para suelos y membranas impermeabilizantes.

Destacar de la planta de reciclaje de neumáticos semiautomática Shuliy

Nuestra planta de reciclaje de neumáticos está diseñada para equilibrar eficiencia, costo y rendimiento ambiental:

- Configuración flexible: Las máquinas se pueden personalizar para producción a pequeña, mediana o industrial.

- Alta productividad: Incluso el modelo más pequeño puede procesar hasta 8000 kg de material por hora.

- Durabilidad: Equipado con cuchillas de aleación resistentes al desgaste y construcción robusta para una larga vida útil.

- Eficiencia energética: Los sistemas de motor optimizados reducen el consumo de energía durante el proceso de trituración.

Convierte Neumáticos Usados en Recursos Valiosos: Aplicaciones y Oportunidades

Invertir en nuestros equipos abre un mercado diverso para convertir neumáticos usados en productos de alta demanda. Aquí está el valor que puede crear:

- Polvo y Gránulos de Caucho de Alto Valor: Este es su producto premium, utilizado para fabricar pistas de atletismo de colores, baldosas seguras para parques infantiles, caucho regenerado de alta calidad y membranas impermeabilizantes duraderas.

- Combustible Derivado de Neumáticos (TDF) de Alto Poder Calorífico: Los trozos de neumático triturados son un combustible alternativo limpio y de alta energía buscado por hornos de cemento, centrales eléctricas y calderas industriales.

- Ingresos Directos por Acero de Desecho: El alambre de acero separado y enfardado es una materia prima de alta calidad para acerías, lista para la venta inmediata y flujo de caja.

Aplicaciones del Polvo de Caucho

El polvo de caucho producido por nuestra línea de producción de polvo de caucho es un material versátil y de alto valor con amplias aplicaciones en múltiples industrias.

En la industria deportiva y de ocio, el polvo de caucho fino se utiliza ampliamente para crear superficies de pistas de atletismo, pisos de parques infantiles y relleno de campos deportivos, ofreciendo una excelente absorción de impactos, resistencia al deslizamiento y durabilidad. En el sector de la construcción, es un aditivo esencial para el asfalto modificado.

Para la industria manufacturera, el polvo de caucho se puede procesar en alfombras de caucho, baldosas y productos moldeados tanto para uso industrial como doméstico. También juega un papel en la producción de caucho regenerado, que puede reintroducirse en la fabricación de neumáticos u otros productos de caucho.

Además, el alambre de acero extraído durante el proceso de reciclaje se puede vender a recicladores de metales, mientras que la recuperación opcional de fibra de nylon proporciona otro flujo de ingresos para aplicaciones textiles o de refuerzo.